Institute of Sensing Measurement, Control and Precision Machining Technology |

The research and education activities of this institute mainly focus on sensing measurement, control technology, and high precision machining technology. The institute currently has 11 staffs, 3 of which are professors, 7 associate professors and 1 engineer. ? The institute undertook more than 10 major ¡° vertical projects¡±, including National Science and Technology Major Projects, Natural Science Foundation of China, the Ministry of Science and Technology Innovation Fund and Major Projects of Defense. At the same time, the institute engaged in numerous "horizontal tasks". Due to the research achievements, the institute formed distinctive features of the scientific research directions. ? The institute published many significant impact academic papers. Additionally, the institute gained various invention patents and national, provincial, municipal science and technology awards. Many achivements in scientific research, which intended to meet the requirements of large enterprises and scientific research institutes have transformed into a series of scientific research products. Therefore, significant social and economic benefits have been achieved. ? The institute offers 14 undergraduate and graduate courses. Currently, the institute has more than 60 PhD and master candidates. And more than 100 graduates from our institute have become important contributors of the enterprises and research institutes. |

Members |

Name |

Tel |

Room Number |

|

Wang Dianlong |

dlwang@dlut.edu.cn |

0411-84706597 |

Building 1£¬223-2 |

Duan Fuhai |

duanfh@ dlut.edu.cn |

13889601926 |

Building 1£¬121-2 |

Xu Zhixiang |

zxxu@dlut.edu.cn |

0411-84709563 |

Building 1£¬221 |

Zhang Jun |

zhangj@dlut.edu.cn |

13500771332 |

Building 1£¬223-3 |

Dong Hai |

donghai@dlut.edu.cn |

13998540476 |

Building 2£¬312-1 |

Li Man |

liman@dlut.edu.cn |

13998406061 |

Building 2£¬312-1 |

Zhang Hong |

jxzh@dlut.edu.cn |

0411-84708413 |

Building 1£¬228 |

Sang Yong |

sang110@163.com |

18018985107 |

Building 1£¬119 |

Lu Xiaohong |

lxhdlut@dlut.edu.cn |

15668685622 |

Building 1£¬226 |

Ren Zongjin |

renzongjin@dlut.edu.cn |

15524748553 |

Building 1£¬226 |

Miao Huaming |

miaohm@dlut.edu.cn |

0411-84709516 |

Building 1£¬134 |

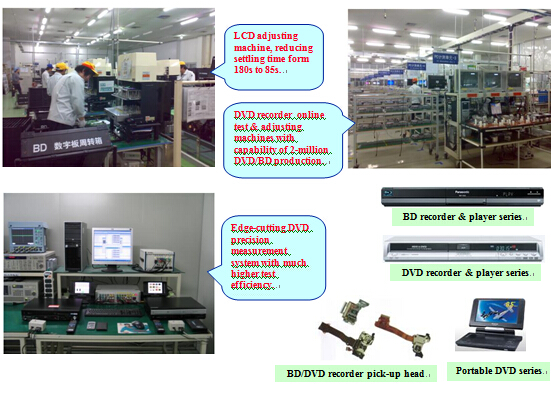

Research Field 1¡¢ Sensors and actuators theory and technology 2¡¢Electrical and mechanical testing and control technology 3¡¢Precision machining and micro machining technology 4¡¢Precision and ultra precision tooling technology 5¡¢Hydraulic system design and analysis 6¡¢Mechanical and electrical drive and electric hydraulic servo control technology 7¡¢High reliability and high power electric and electric hydrostatic actuator technology 8¡¢Electronics manufacturing automation |

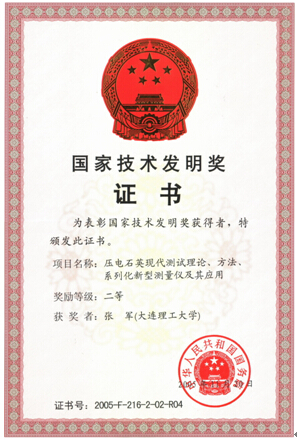

Main Achievements A second prize of National Technological Innovation

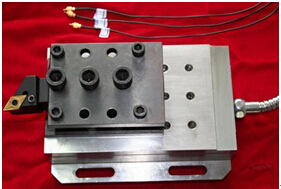

The typical scientific research products and applications The developed piezoelectric cutting dynamometer and system have been widely used in the field of mechanical manufacturing, aerospace, research and teaching.

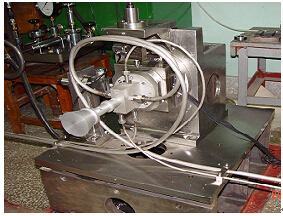

Fig. 1 A series of piezoelectric cutting dynamometers and systems Cooperated with related enterprises of China Aerospace Science and Technology Corporation for a long time, mainly researched on Orbit/posture control rocket engine thrust vector, and solved the major problem of accurate dynamic thrust measurement and control.

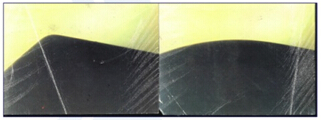

Fig. 2 Orbit/posture control rocket engine thrust measuring system Have gained significant breakthroughs in the fields of grinding theory and grinding technology of super hard material tool, manufacturing technology of super hard material tool, and processing mechanism and technology of difficult-to-machine materials. The developed various precision and ultra precision cutting tools have reached the international advanced level, and have been widely used in the foreign enterprises and large and medium-sized domestic enterprises.

Fig. 3 The supreme quality of the produced and sharpened PCD and PCBN tools¡¯ cutting edge has reached the highest standards of the world

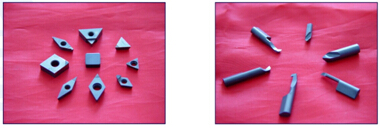

Fig. 4 Superhard material indexical inserts Fig. 5 Special polycrystalline diamond cutter

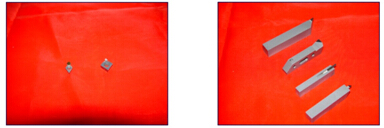

Fig. 6 The single crystal diamond blades Fig. 7 Superhard material welding tool Developed a three-axis micro-milling machine (Fig. 1). The outer dimension of the machine is , the working envelope is . The spindle speed varies from 40,000 to 140,000 rpm. The institute carried out in-depth study and exploration on micro-milling processing mechanism and micro-milling technology and obtained a series of achievements.

Fig. 8 The self-developed micro CNC milling machine Developed the comprehensive performance testing system of power tool rest, achieved the dynamic detection of positioning accuracy, angular velocity and acceleration, temperature, vibration, noise, etc.. , and solved a series of dynamic detection technical problems.

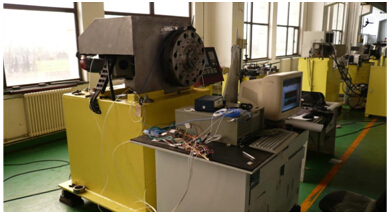

Fig. 9 Comprehensive performance testing system of power tool rest Developed a comprehensive performance testing system of chain-type magazine and ATC. In addition, built a comprehensive performance testing system of circular tool magazine and ATC. Achieved the testing of performance parameters such as the kinematical characteristic of manipulator, the magazine positioning error, vibration on the tool oriented part and noise. The developed performance test systems of tool magazine and ATC are used to estimate the performance of tool magazines and ATCs produced by Dalian Golden CNC Group Corp.

Fig. 10 Comprehensive performance testing system of Chain-type tool magazine and ATC

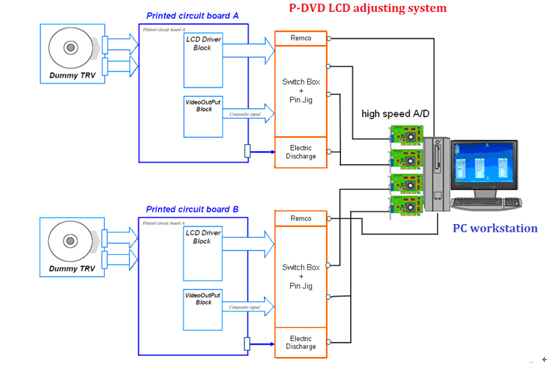

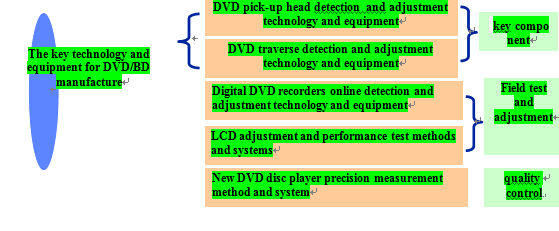

Fig. 11 Comprehensive performance testing system of circular tool magazine and ATC The critical equipment for DVD/BD manufacture

Fig. 12 The adjustment system |

Contacts Name: Tel: E-mail: Address: Web address: |