| Key Laboratory for Precision and Non-Traditional Machining Technology |

| Introduction of lab Key Laboratory for Precision and Non-Traditional Machining Technology, Ministry of Education, was authorized by the Ministry of Education in November, 2003, and subsequently passed the assessment of the Ministry of Education to open up to the world in July, 2007. It is attributed to Dalian University of Technology. The lab depends on the second grade national key discipline, mechanical manufacturing and automation, and first grade key disciplines, including mechanical engineering and instrument science and technology. It focuses on the precision and ultra-precision, as well as non-traditional machining technologies. We aim to develop innovative theory, technology, devices, and cultivate high level talents. Our object is to establish a domestically first-class and internationally renowned foundation for device manufacturing, advanced manufacturing technologies, development of technology, and a cradle of high level experts. The lab has undertaken 258 projects since 2009, and the contract budgets are 194.64 million CNY. The projects consist of 1 973 Program (Principal unit), 16 sub-projects of 973 Project, 8 sub-projects of 863 Program, 5 sub-projects of National Key Technology R&D Program, 10 sub-projects of National Science and Technology Major Project, 9 Key Programs of National Natural Science Foundation of China (NSFC), 48 General Programs of NSFC, 21 Projects for Young Scientists Fund of NSFC, 9 sub-projects of National Defence Basic Foundation of China and Pre-Research Foundation of China, the PLA General Armament Department, and tens of projects of provincial level. The lab received a 1st Prize of National Technology Invention Award, a 2nd Prize of National Science and Technology Progress Award, one time 1st Prize, two times 2nd Prize, and one time 3rd Prize of provincial or ministerial level. Eighty one National Invention Patents were awarded. Four hundred and eighteen peer-reviewed journal papers were published, where seventy eight were indexed by SCI, and three academic books were written and published during the past three years. The building area in the lab is 6094 square meters, and assets valued are about 60 million CNY for internationally advanced setups, such as high speed milling center (HSM500, MIRON, Switzerland), three-axis YAG laser forming system (RP-503F, Singapore), laser machining system (JK702H, UK), precision micro-processing platform (self-developed), precision grinder for silicon wafers (VG401, Japan), magnetron sputtering (AB-18, Kurt J. Lesker Inc., USA), Nano-print optical lithography (Obducat AB Eitre 6, Sweden), 3D surface profilometer (Newview 5022, USA) etc. These instruments contribute greatly for the creative researches. The lab contributes significantly for the national manufacturing, and forms a team of advanced manufacturing technologies, after the establishments of 9th, 10th, 11th Five-Year Plan, 211 and 985 Projects. |

| Members: The lab includes 55 staffs, among which there are 30 professors, 18 associate professors, 2 lectures, 4 technicians (3 senior engineers and 1 engineer), and 1 administrator. It has one academician of Chinese Academy of Sciences, one academician of Chinese Academy of Engineering, one professor of Cheung Kong Scholar Program, one member of Thousand Person Plan, and 7 members of Program for New Century Excellent Talents in University. The recipients of Ph.D. degree are 96 percent in all the staffs. |

| Research Field The research areas consist of four aspects: 1. Precision, ultra-precision machining theories and technologies; 2. Non-traditional machining mechanisms and technologies; 3. Precision measurement and digital control for processing; 4. Micro-system and micro-manufacturing technologies. |

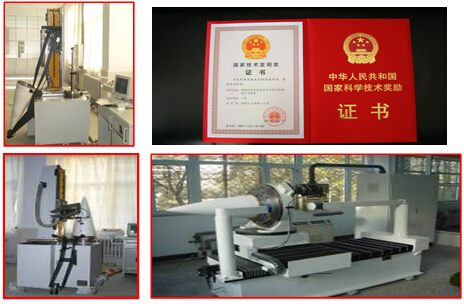

Main Achievements

The outcome named Precision Manufacturing Technology and Device for Products with Complicated Crooked Surface Made of Hard-Brittle Materials received the 1st Prize of National Technology Invention Award, as well as the winner of Ten Science and Technology Breakthroughs in University of China.

Ultra-precision grinder, VG401 MKII, Okamoto, Japan

NC machining center, Cincinnati Inc., USA |

| Contacts Name: Tel:86-411-84708011 E-mail: Address: School of Mechanical Engineering, Dalian University of Technology, Dalian 116024, P.R. China Web address: |